Automated Shape Setting

Automation build for Curved Needles Shape Set in Sand Bath

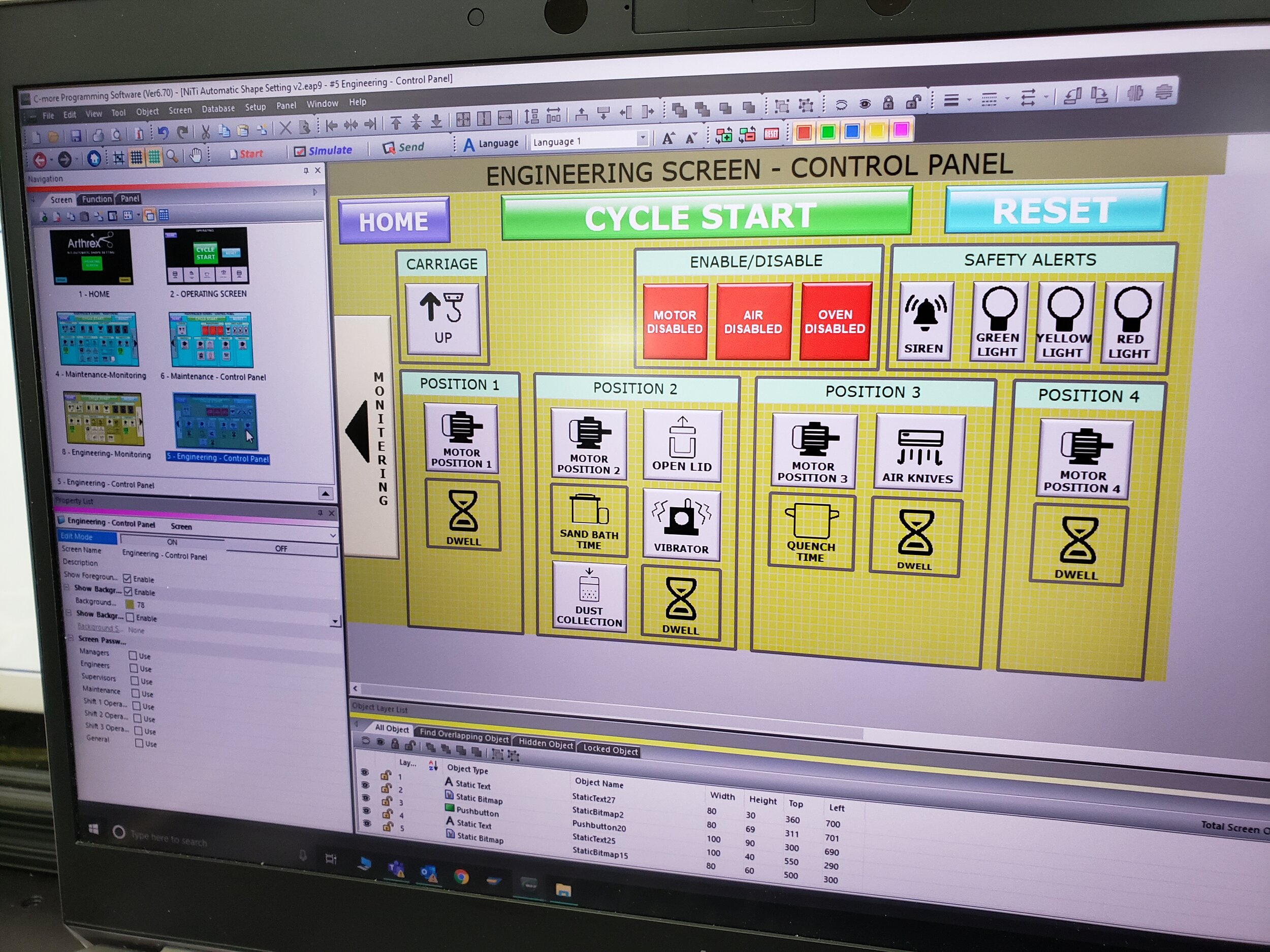

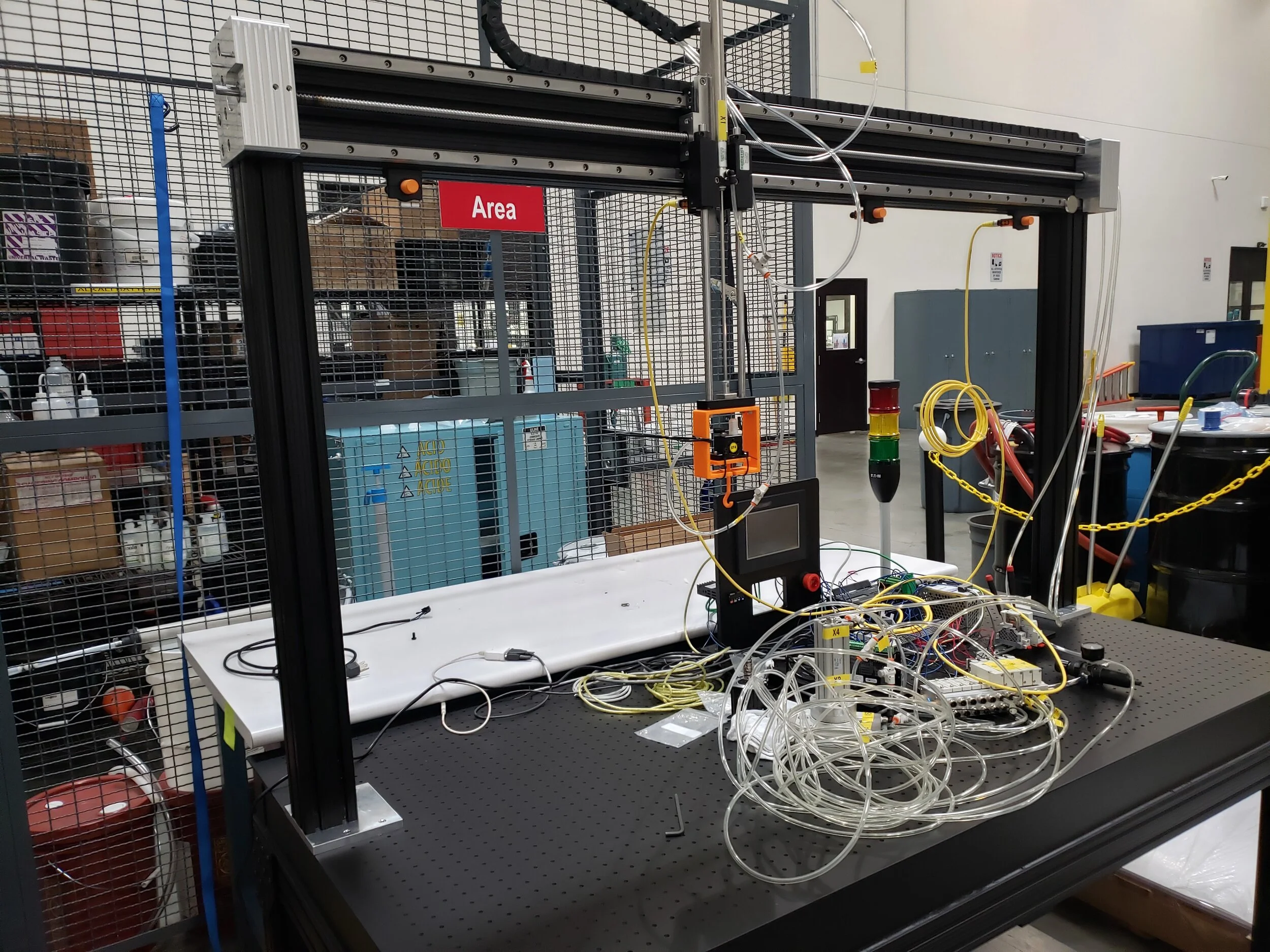

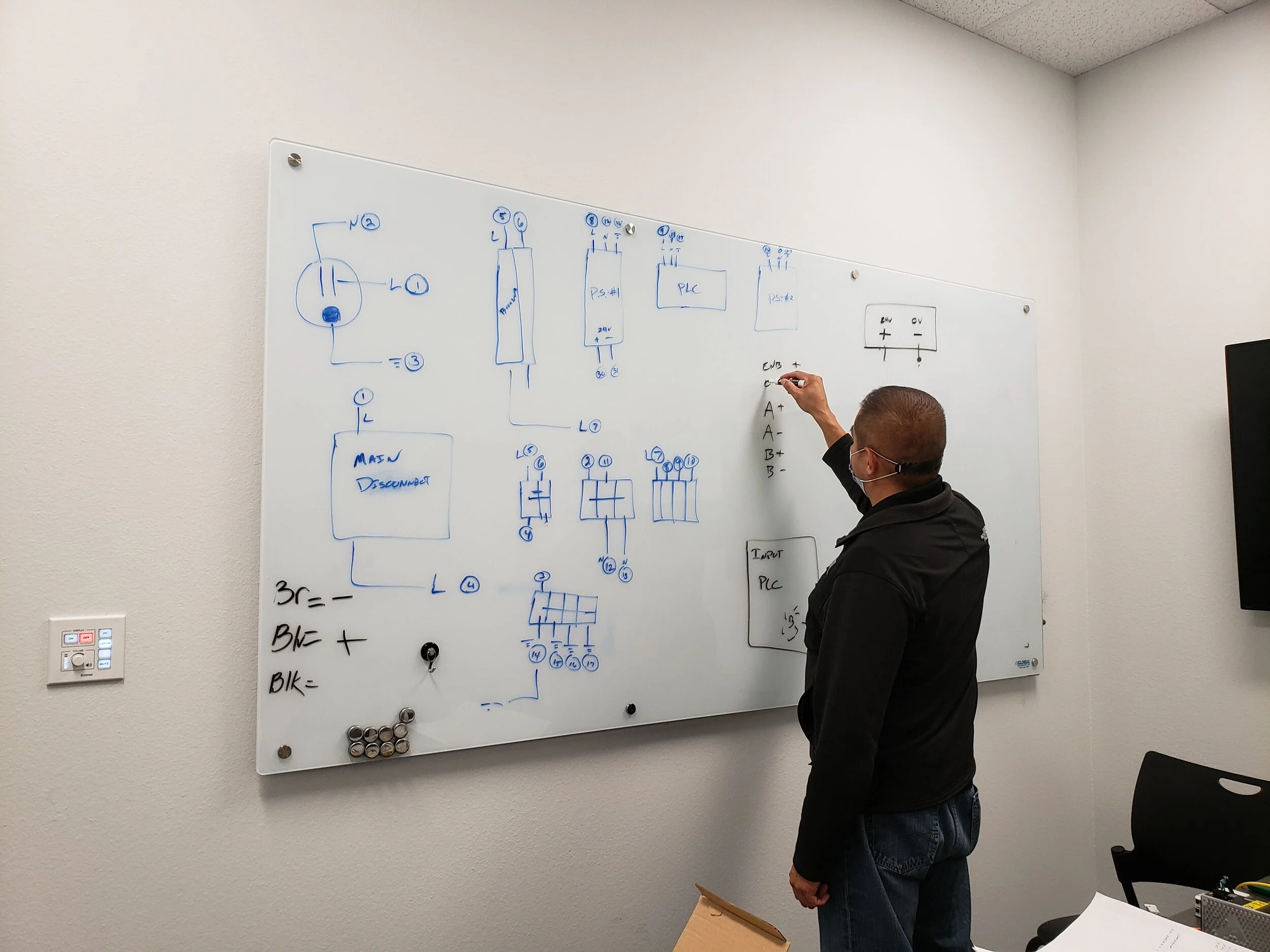

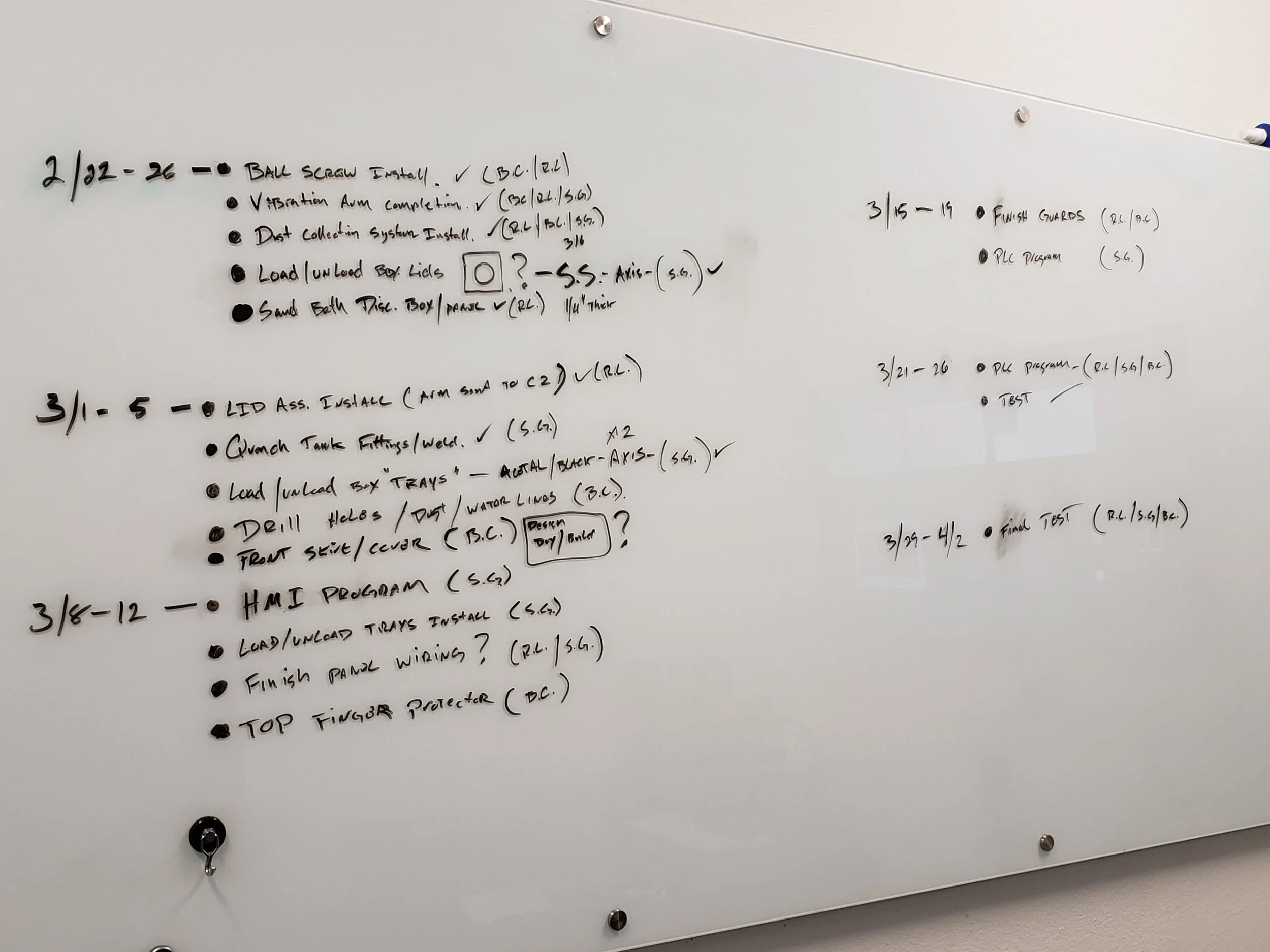

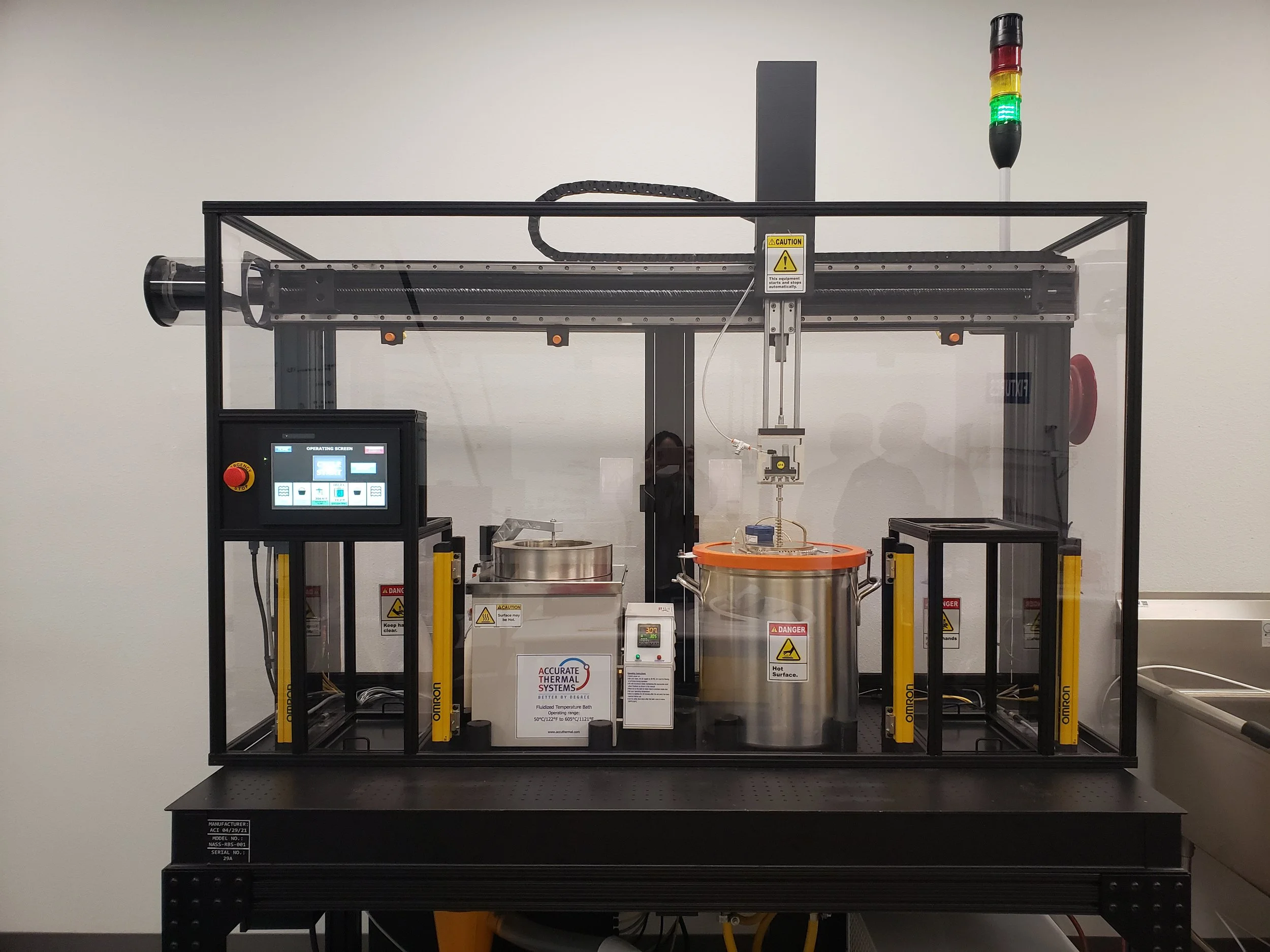

At Arthrex, I had the incredible chance to learn about automation and building a machine almost from scratch! There were many components to this project including fabrication of custom parts, PLCs, heating/chilling parts, HMI configuration, pneumatics, and safety sensors. The above video shows one of the first runs that were successful before we put on safety plexiglass.

This project was to create an automated “pick-and-place” type machine which would work in the following steps:

Operator would drop off basket full of straight needles in a fixture that keeps them in a curved configuration

Machine would take basket and lower it into a heated aerated sand bath at 1100F; shaker motor/dust collector would turn on as the basket is taken out to shake off excess sand

Machine would lower basket into quench tank (temperature regulated by a chiller; air knives would turn on as basket is taken out to blow off excess water

Operator would be able to grab the parts in the pick up area

Needles will be set into curved shape.

This was created to keep the operator separate from the heated sand bath as a safety precaution to properly set the curved shape in the metal needles.

This automation build was a teaching build from our Principle Manufacturing Engineer, so it was a great experience to ask questions about everything!